By Lou Farrell, Senior Writer, Red Planet Bound Blog

Space exploration requires immense effort and some of the most advanced technologies humans have ever engineered. While the moon was first explored decades ago, Mars and other planetary bodies remain beyond human contact. To make this dream a reality, organizations must prioritize aerospace equipment consistency and safety redundancies if they want to stand a chance against the endless vacuum.

The Importance of Aerospace Equipment Consistency

Those interested in seeing humans reach further into space and eventually land on Mars may be curious about the delay. It has been years since the moon landing, so why is this pivotal landmark continuing to elude the most capable experts on the planet? The aerospace sector is among the most rigorous in safety standards, for good reason. Safety tests have even led to the rescheduling of the next moon mission, giving experts more time to perfect fuel systems.

The smallest leak in a fuel pipe or tiny gap in an airlock seal could prove fatal for the crew. Additionally, much of the research and all of the groundbreaking technology humans thrust into space is lost to time. These realities are why redundant manufacturing practices are inherent to spacecraft manufacturing.

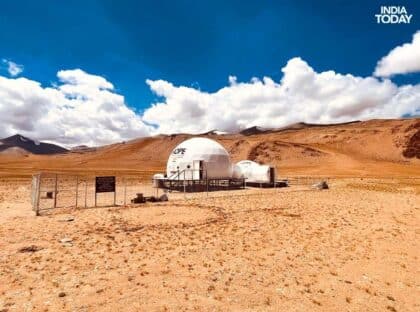

Even unmanned rovers need equal attention. They are withstanding harsh environments, especially on Mars’ hot, rocky surface. They must be responsive to remote orders without delay and capable of handling intense conditions, such as radiation and high winds. This machinery has no hands-on support available. Therefore, it has to be forged and assembled with laser-focused quality control. Otherwise, the mission fails, risking millions of dollars for organizations like NASA. These losses jeopardize the viability of future trips.

Finally, careless assemblies, miscalibrated sensors and flimsy materials compromise what researchers gain from piloted and unmanned missions. If systems are not durable enough to maintain their data-collection capabilities, the information gathered is of no value. Inevitably, it will be unable to support further research due to its low scientific accuracy, delaying humanity’s approach to Mars.

The Dedication to Safety Redundancies

Consistency is the foundation of reliable data and research that creates forward momentum in the aerospace industry and scientific community. Both types of missions need safety protocols, but crewed missions are even more crucial to prepare for when considering safety redundancies. NASA and its collaborators must construct systems that eliminate failure as an option.

This goal means eliminating any single point of failure on each spacecraft. Efforts must not become moot because of the unavailability of one software, mechanism or resource. There must be multiple ways to access critical systems, including assets like oxygen.

A remote rover should have multiple batteries, computers and mobility mechanisms to traverse surfaces uninterrupted. Space debris could compromise its exterior shell, or radiation could interfere with electrical components. Protecting even the smallest parts will allow piloted spacecraft and other devices to remain communicative with professionals on Earth. The Ingenuity helicopter on Mars is a primary example of embedding redundant controls and navigation systems to ensure it stays on track while anticipating anomalies.

Precise and Accurate Components in Manufacturing

Several engineering and manufacturing techniques contribute to quality aerospace components. Without these production advancements, it may not be possible to craft machinery capable of ascending into space without risking the crew. However, every technique still has room to improve in delivering even better spacecraft components for safer missions.

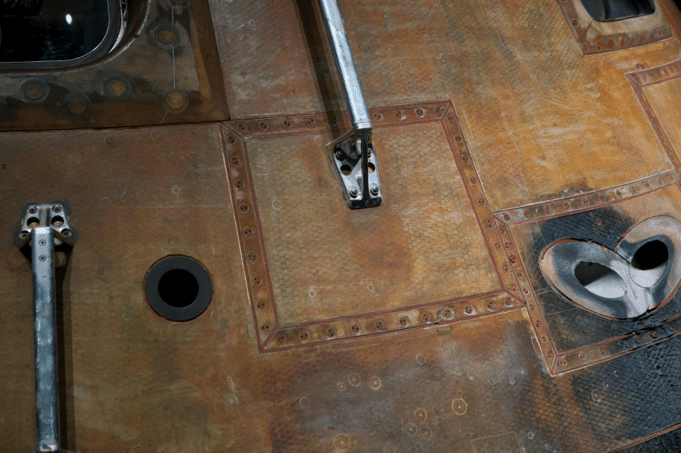

Investment Casting

This method has been in the industry for a long time, leveraging wax patterns, slurries and molds to make aerospace parts. The component’s quality is only as precise as the mold’s construction. If there are defects, it does not matter how strong the molten metal becomes when it eventually leaves its casing. However, the perfect model can lead to the ideal parts every time, making mechanisms with reliably smooth finishes, exact dimensions and trustworthy ingredients.

Investment casting is essential for parts with mixed metals, such as turbine blades for jet engines and exhaust nozzles. The molds can produce parts with niche constructions in a single shape with no breaking points. Alternatively, it can manufacture complex objects in multiple pieces using strong adhesives.

Electrical Discharge Machining (EDM)

EDM does not require manual finessing or intense strength to execute. Because it relies on electrical charges, it encourages safety on manufacturing floors by being a completely automated process. These sparks can cut the sector’s most challenging metals, enabling the industry to take advantage of nature’s most robust raw materials without being inhibited by human limitations in manipulating them into what a spacecraft needs.

Because EDM does not need force, there are fewer chances for defects to form, like cracks or warps. Preventing these cases is vital to preserving the quality of essential parts, such as fuel injector nozzles and hinges that keep satellites and ships bound.

Computer Numerical Control (CNC) Machining

CNC machining has become one of the most reliable ways to craft essential spacecraft components, including rocket engines designed to deliver high performance in harsh environments. It supports aerospace equipment consistency and redundancy by removing human error from the manufacturing process.

CNC machines can produce hundreds of replicas of the same part — whether it be valves or bulkheads — without deviating from the programmed blueprint. This strategy is ideal for creating backup parts for astronauts to replace faulty components.

Additive Manufacturing

The advent of 3D printing changed the industry by introducing even more innovative materials onto production floors. Engineers have unprecedented flexibility to create stronger components by increasing durability through internal lattice structures or by adding additives to boost the material’s performance. Most printers use metal powders to print complex parts from digital models. They can do so in one piece, minimizing failure points.

As additive manufacturing advances to support even larger projects, aerospace manufacturers could produce parts as large as superalloy blades or injector plates, similar to the parts used in SpaceX rocket designs. The company has invested $8 million in additive manufacturing for the aerospace industry, demonstrating industry-wide curiosity in advancing the technology.

How Precision Creates the Redundancy Humans Need to Get to Mars

These methods are the cornerstone to creating the nearly invincible shells that protect Earth’s astronauts. They are also the best way to promote redundancy, enabling engineers to install even more high-quality fixtures on spacecraft and providing greater peace of mind for those on board. Eventually, innovations like 3D printers and CNC machines will output precise and well-tested components that help humans get to Mars by:

- Increasing the chances of the crew’s survival, especially in long journeys where more tools and backup equipment are likely to be used.

- Making spacecraft more functional, easier to handle and durable by optimizing parts manufacturing for lightweight and stronger alternatives.

- Considering long-term mission reliability and how the future’s missions will be even more time-consuming and arduous.

- Providing equally high-quality replacement parts so astronauts can trust backup inventories when parts fail mid-mission.

Touching the Infinite

Being able to put human feet on Mars and eventually explore other parts of the cosmos is only possible through ingenuity. Innovators must design more reliable ways to ensure astronauts’ safety in the most threatening environment imaginable. If high-quality materials and machinery can reliably produce flawless components and assemble them with utmost precision, humanity could venture farther into space than ever before.

Author’s Personal Note: I have been guilty of wanting to call something “finished” the moment it seems complete at first glance. It’s hard to deny the rush of satisfaction when you complete a task or create something, isn’t it? But this article shows that it is absolutely critical to prepare for any and all circumstances, especially in aerospace engineering/manufacturing, and that you can’t just assume something is without fault because it worked once.

Redundant systems, and an overall focus on safety, is paramount.

Images: Gower Brown (Unsplash), Brian McGowan (Unsplash)